Tel: +86-13526515820

E-mail: hjfsun@gmail.com

Addresss:Kangdian Industrial Park, Gongyi City, Henan Province,China

JUSHANG MACHINERY

Tel: +86-13526515820

E-mail: hjfsun@gmail.com

Addresss:Kangdian Industrial Park, Gongyi City, Henan Province,China

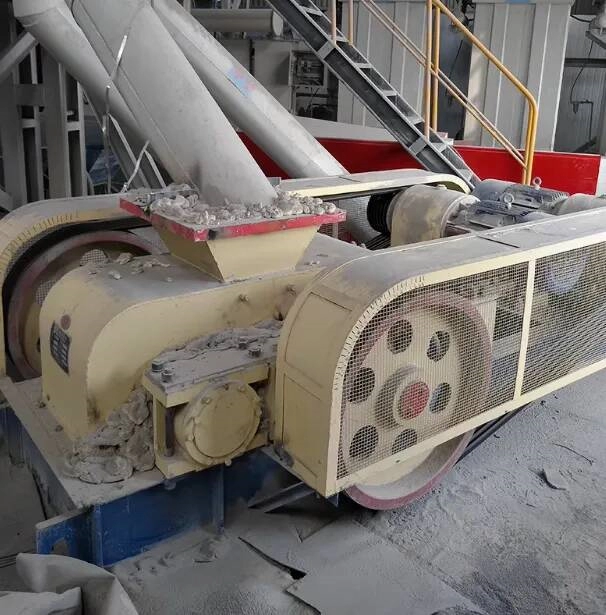

Failure to adjust the thickness of the roller seam pad in a timely manner based on the wear of the roller and the actual condition of welding, resulting in significant pressure fluctuations during the operation of the equipment and severe vibration of the body, ultimately shortening the service cycle of the machine.

During the welding operation, due to the limited level of welding technology, or the deviation of the measurement of the diameter and roundness of the machine, the uniformity of the welding of the roller surface is poor, which in turn causes uneven force on the roller surface.

The quality of the wear-resistant electrode is poor, and it cannot be well integrated with the base material of the roller surface, resulting in stratification or cracks.

The temperature of the roller surface is too low, or the surface material of the machine is not cleaned thoroughly enough during the welding process, which leads to slag and sandwich problems.

The execution of the iron removal link is not in place, causing iron debris to enter the interior of the double-roller crusher, causing wear and tear of machine parts.

The above are the main reasons that affect the service life of the double-roller crusher.After clarifying these factors that lead to shorter life expectancy, it will be more targeted to solve related problems.If you have any questions about equipment technology, please feel free to call for consultation, and we will provide you with detailed answers.

Phone:+86-13526515820

Email:hjfsun@gmail.com

Addresss:Kangdian Industrial Park, Gongyi City, Henan Province,China

Copyright 2023 Gongyi Jushang Machinery Equipment Co., Ltd Privacy